A metal core printed circuit board (MCPCB) also known as thermal PCB, incorporates a metal material as its base as opposed to the traditional FR4, for the heat spreader fragment of the board. Heat builds up due to some electronic components during the operation of the board. The purpose of the metal is to divert this heat away from critical board components and towards less crucial areas such as the metal heatsink backing or metallic core. Hence, these PCBs are apt for thermal management.

1. Aluminum substrate -The aluminum printed circuit boards offer good heat dissipation and heat transferring ability. Since they are light in weight, the aluminum core PCBs find their purpose in LED lighting, audio frequency apparatus, and communication electronic equipment.

2. Copper base (copper core or heavy copper) -The copper core boards feature better performance than aluminum. But customers generally choose aluminum since copper is relatively expensive. Also, copper cores are heavier and involve a tough machining process. Copper also corrodes easier than aluminum.

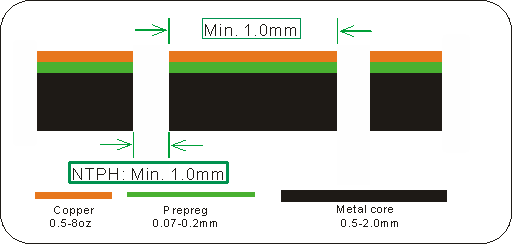

Single-sided PCBs on metal base

A copper foil is laminated onto a metal base using a prepreg.

Normally, this variant only has drill holes for fastenings.

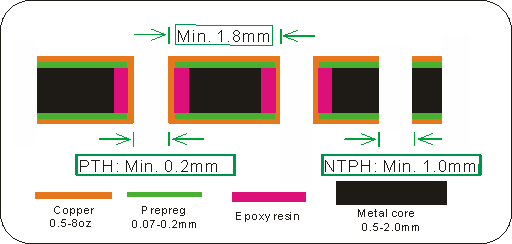

Double sided structure with metal core

Copper foils are laminated onto both sides of an metal core using prepreg. The PCB can be through-plated.

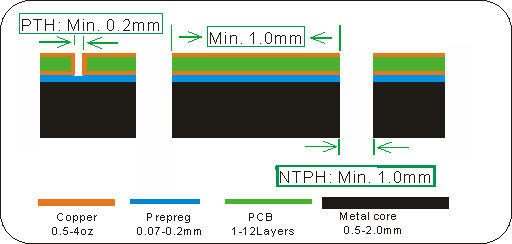

Completed PCBs are press-moulded to a metal carrier using a prepreg. Benefit: Multilayers can also be used (only single-sided SMD). Disadvantage: Poor heat dissipation, as the heat has to be dissipated through the entire PCB.

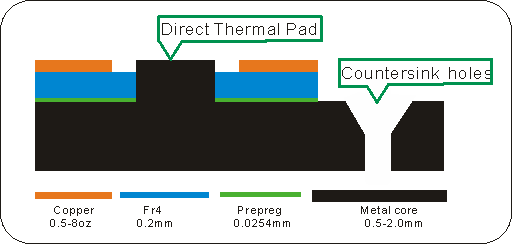

LEDs Chip Thermal Pads solder to the Aluminum or Copper substrate directly,

No dielectric between LEDs heat out pads and the Metal core.

Means,thermal resistance is very small and,

Thermal conductivity could be 175 W/m.k ( direct to aluminum) to 385 W/m.k( direct to copper ).

●Thermal conductivity: Standard materials: 1-3W/m.k ; Specified materials : 4-12W/m.k

●Copper thickness: 18–105 μm

●Minimum drill hole diameter PCB (PTH): ≥ 0.2 mm

●Minimum drill hole diameter PCB (NPTH): ≥ 1.0 mm

●Minimum drill hole diameter for aluminium: ≥ 1.0mm

●Drill hole/drill hole spacing: > 1.2 mm

●Minimum router diameter: ≥ 1.6 mm

●Surfaces: HAL, HAL free lead, OSP, ENIG (not recommended!)

●Machining:Produced like standard PCBs in multiples or individually, as well as being milled and scored.