Taconic 2 Layer PCB

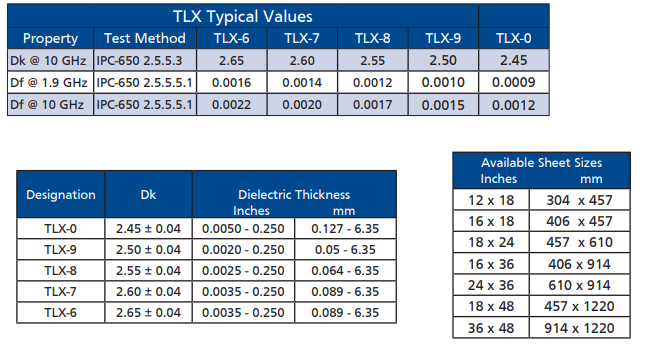

TLX offers reliability in a wide range of RF applications. This material is versatile due to its 2.45 - 2.65 DK range and available thicknesses and copper cladding. It is suitable for low layer count microwave designs.

key word:

Taconic 2 Layer PCB

Category:

Product Description

| Base Material | Taconic TLX 0 |

| Board Thickness | 0.5 mm |

| Copper Thickness | 1OZ |

| DK | 2.45 |

| DF | 0.0009-0.0012 |

| Solder mask Color | None |

| Silkscreen Color | None |

| Surface Finishing | ENIG |

| Min.Quantity of Order | No MOQ |

| Certificate | UL, ISO 9001, ISO 14001 |

| Difficulty | 5mil/5mil, Special Material |

Benefits:

TLX offers reliability in a wide range of RF applications. This material is versatile due to its 2.45 - 2.65 DK range and available thicknesses and copper cladding. It is suitable for low layer count microwave designs.

Excellent mechanical & thermal properties

Low & stable DK

Dimensionally stable

Low moisture absorption

UL 94 V-O rating

Tightly controlled DK

Low DF

For low layer count microwave designs

Applications:

Antennas

Mixers, splitters, filters & combiners

Passive components

Dielectric Constant & Dissipation Factor Across Product Line:

KingCredie follow the international standard manufacturing

● IPC-4101 Specification for base materials rigid / multi-layer

● IPC-600G Acceptability of Printed Boards / Class 2

● IPC-6011 Generic Performance Specification for Printed Wiring Boards

● IPC-6012B -Qualification and Performance Specification for Rigid Boards/class 2

● IPC6013A- Qualification and Performance Specification for Flexible Printed Boards/class 2

● IPC6016- Qualification and Performance Specification for High Density Interconnect(HDI) Layers or Boards/ class 2

● IPC-SM-840 Qualification and Performance of permanent polymer coatings

● MIL-PFR-55110 Military Performance and Specifications-Tucson

● IPC-6018 Microwave End Product Board Inspection and Test-Tucson

● IPC-TM-650 Test methods manual.

Related products

PRODUCT CONSULTATION

info@kingcredie.com

info@kingcredie.com

Search keywords

Search keywords

Get Instant Quote

Get Instant Quote